Description

LVXING has manufactured extruder screens for more than 15 years in China.Products mainly include disc type extruder screens and cylindrical extruder screens.They are available in single layer extruder screen filters,multilayer spot welded screen packs,Rim extruder screen packs.These extruder screens are effective for polymer extrusion as polyester,polyamide, polymer,plastic blown,Varnishes,paints.

Material: Stainless steel 201 302 304 304L 316 316L,mild steel,galvanized steel,aluminum,copper,etc.

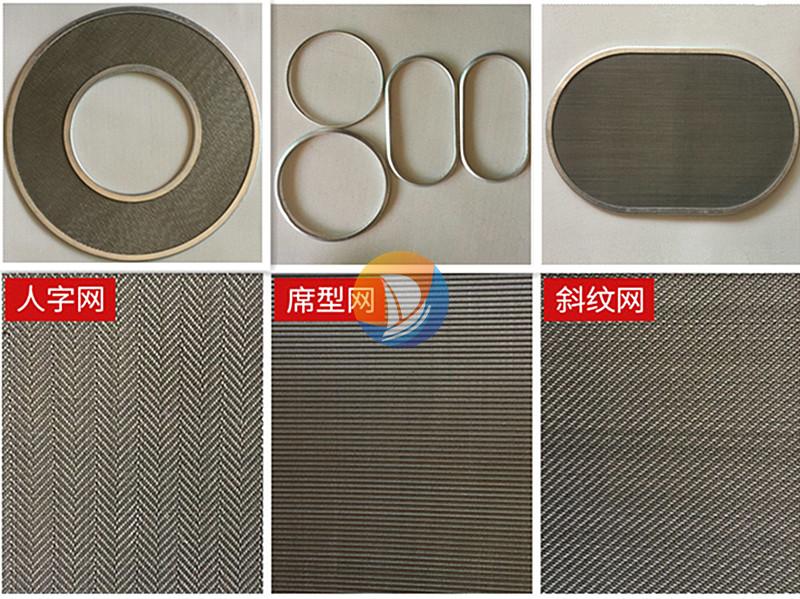

Filter media: Plain weave wire mesh,twill weave wire mesh,dutch weave wire cloth,etc.

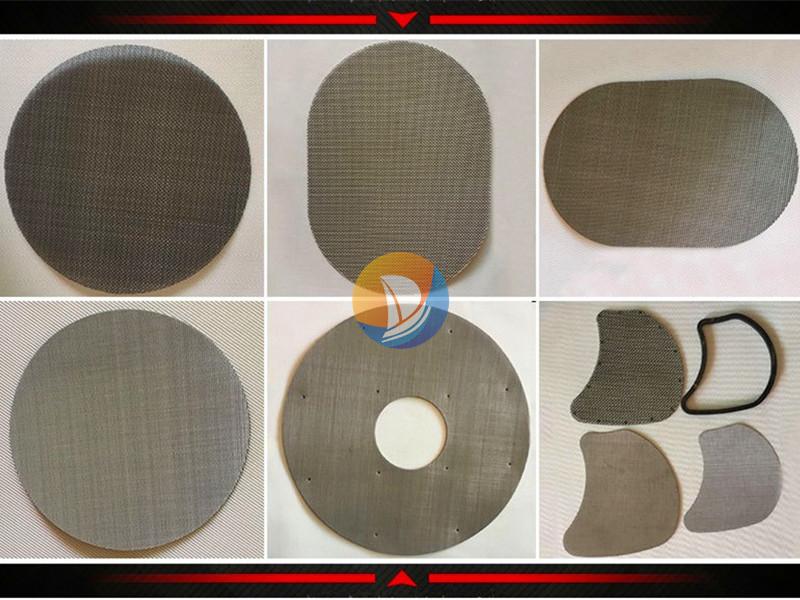

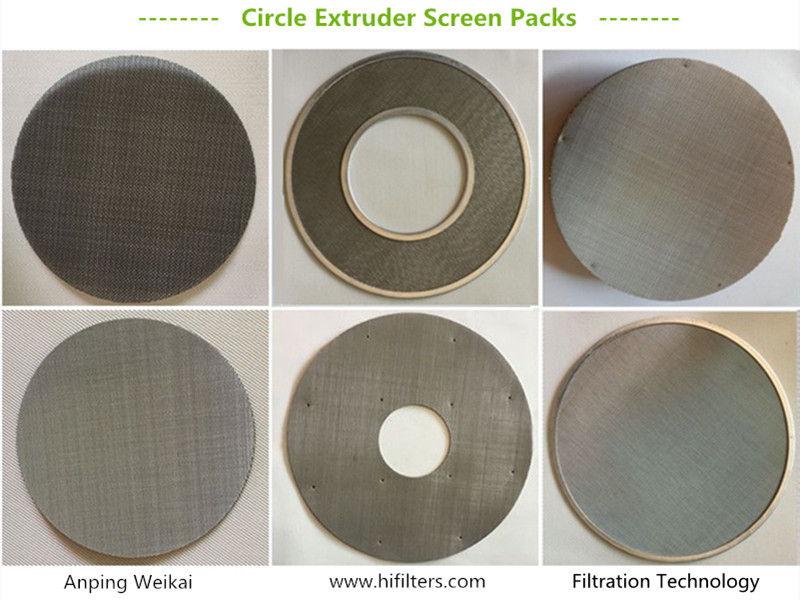

1. According to shape,Extruder Screens can be divided into

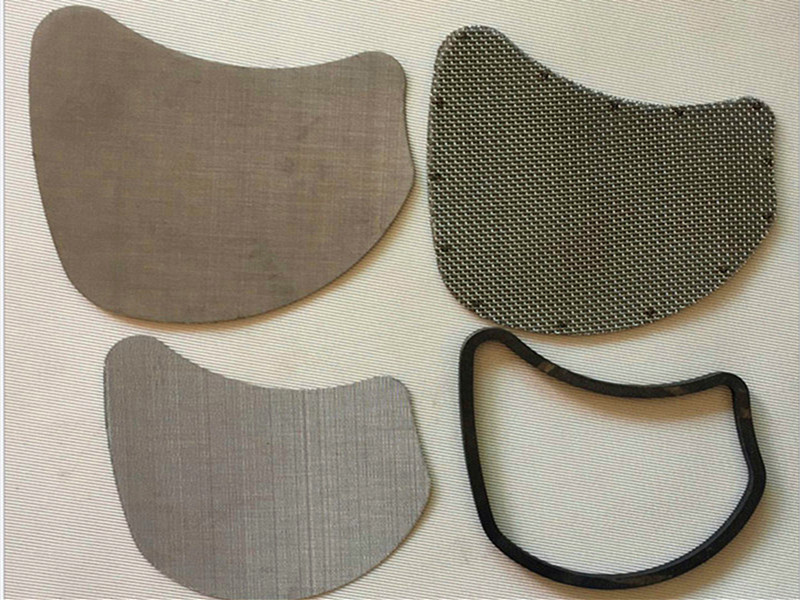

Disc Extruder Screens - Round/circular extruder screens,square/rectangle,toroidal/annulus,kidney shape extruder screens;

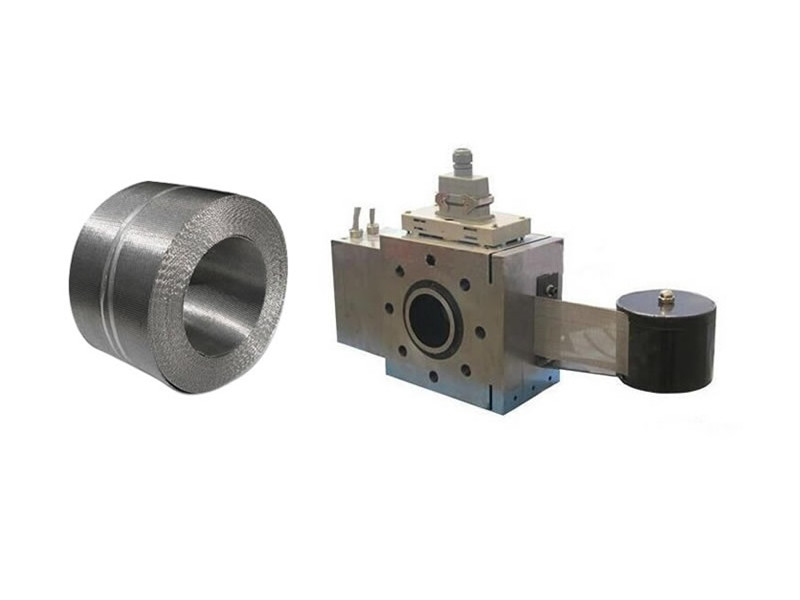

Cylindrical Extruder Screens - Cylinder,drum,bowl,cone,basket sahpe extruder screens.

2. According to edge processing,Extruder screens can be divided into

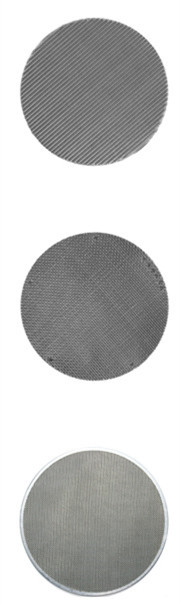

Single Extruder Screen Filters

They are predominantly used in the plastic reclamation industry,often with a dutch weave filter used in conjunction with a plain weave support filter.

These are also used in the extruded profiles and blown film industries where the contamination of of the raw material is less where is often lower pressure within the extruder head.

These are excellent for using in any fields where a specific graduated filtration is required.

Another advantage is that it stops single screen filters being placed into the extruder incorrectly.For example a pack consisting of three meshs could consist of a 10 mesh/20 mesh/10 mesh;meaning that whichever way the wire mesh filter is placed into the extruder head,it will work correctly.

Material: Stainless steel 201 302 304 304L 316 316L,mild steel,galvanized steel,aluminum,copper,etc.

Filter media: Plain weave wire mesh,twill weave wire mesh,dutch weave wire cloth,etc.

1. According to shape,Extruder Screens can be divided into

Disc Extruder Screens - Round/circular extruder screens,square/rectangle,toroidal/annulus,kidney shape extruder screens;

Cylindrical Extruder Screens - Cylinder,drum,bowl,cone,basket sahpe extruder screens.

2. According to edge processing,Extruder screens can be divided into

Single Extruder Screen Filters

They are predominantly used in the plastic reclamation industry,often with a dutch weave filter used in conjunction with a plain weave support filter.

These are also used in the extruded profiles and blown film industries where the contamination of of the raw material is less where is often lower pressure within the extruder head.

These are excellent for using in any fields where a specific graduated filtration is required.

Another advantage is that it stops single screen filters being placed into the extruder incorrectly.For example a pack consisting of three meshs could consist of a 10 mesh/20 mesh/10 mesh;meaning that whichever way the wire mesh filter is placed into the extruder head,it will work correctly.

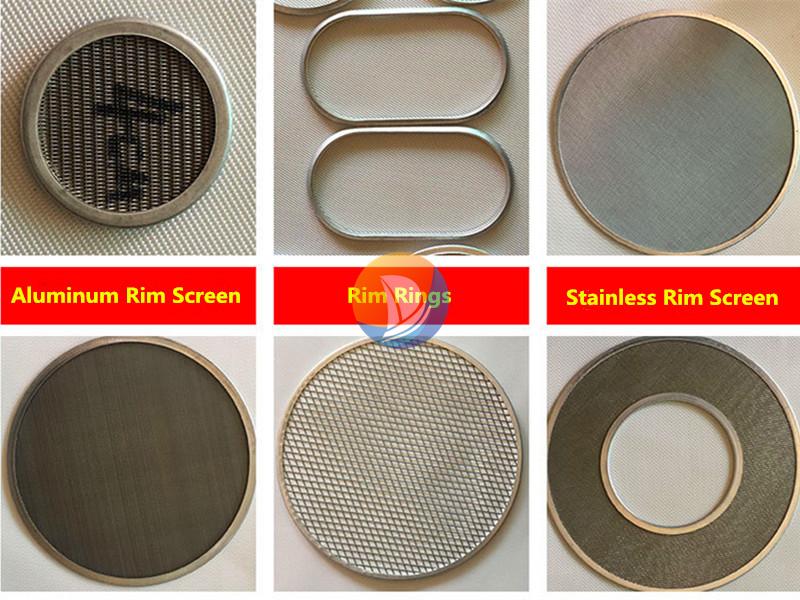

Rim Extruder Screen Packs

These are spot welded packs that have an aluminum or stainless steel rim added to them to give the wire mesh filter extra rigidity and strength.

These are excellent for using where the extruder screen filter is operating at high pressures or if there is a danger of contamination getting around the edge of the breaker plate.

3. According to layers constructure,extruder screens can be divided into Single layer filter disc and multilayers extruder filter packs.

Tags: Single Extruder Screen, Spot Welded Extruder Screen Pack,Rim Extruder Screen Pack